Shawn Crawford, MS candidate, Virginia Tech.

The application of lean in the wood products and furniture industry is a relatively well known concept, specially in the Appalachian Region. Recent surveys suggest that Virginia wood products and furniture industries have heard of terms like lean management, lean manufacturing, and lean thinking however, are unfamiliar with the tools that make up these terms (Fricke, 2010). The segments of the sector with the highest amount of lean awareness and implementation were engineered wood, manufactured homes, household furniture manufacturing as opposed to sawmills and wood container and pallets with the lowest amount of awareness and implementation (Fricke, 2010).

There is a great need for process improvements in the Forest Products industry, specifically lean. Lean thinking is the philosophy, as it applies to manufacturing, of doing more with less (Womack and Jones, 2003). By incorporating lean tools like value stream mapping, production performance and efficiency can be enhanced without throwing high energy consuming automated systems or technology to improve the process. The lack of R&D suggest that the forest products industry has a high potential for saving energy if they use lean tools like benchmarking and create a pull production system as opposed to pushing the product through. Lean manufacturing allows an operation to enhance production performance which has a direct correlation on energy consumption. For example, a production process that doubles throughput while using almost the exact same equipment cuts energy consumption in half.

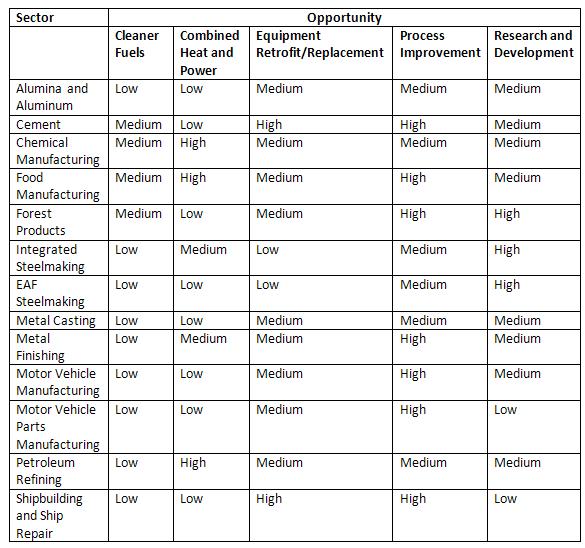

In an attempt to assess energy consumption of the industrial sector within the U.S. to promote clean energy, the EPA evaluated 12 major sectors including forest products. Each sector was assessed based on five major criteria for potential energy efficiency and clean energy. Table 1 shows the potential for the forest products industry to implement process improvements. The forest products industry is relatively high for potential energy efficiency, mainly for process improvements and research development. Focusing on energy efficiency potential in the areas of process improvement and research & development, Table 1 shows a significantly high potential or need for advancement.

As shown in Table 1, the need for combined heat and power (CHP) in the forest products industry is relatively low due to the forest products industries ability to burn wood byproducts for fuel. One of the most common methods of using wood byproducts is in a wood furnace/boiler to power drying kilns. The forest products industry has a distinct advantage over large energy consuming industries, like aluminum, because a majority of their process heating is generated onsite (EPA, 2007).

Producing cleaner fuels in any industry is limited in the amount of alternative fuel sources available. The total renewable energy consumed by the industry is 28% yet, the forest products industry makes up half of the total renewable energy consumed at 14% (EIA, 2010). As mentioned before, wood scraps are the main sources of fuel for the forest products industry, however, the combustion of wood releases a 3.2 g/MMBTU of nitrous oxide which is a contributor to greenhouse gases (EIA, 2011). Nitrous oxide released from wood is significantly higher than that of coal which is 1.5 g/MMBTU (EIA, 2011). Although the forest products industry is a large consumer of renewable energy, the fuel source is a high contributor to greenhouse gases.

Properly retrofitted and replaced equipment is a key opportunity for energy efficiency. When retrofitting existing equipment it is important to focus on prober lubrication of motors and belt sizing (Energy-in-Motion, 2010). When replacing equipment it is important to focus on more efficient lighting and HVAC systems (Energy-in-Motion, 2010). The forest products industries potential for energy efficiency in retrofitting/replacing equipment is average which, could be tied back to the industries lack of research and development.

It is suggested that the forest products industry increases in process improvements which in turn, increases research and development. It is obvious that harnessing employee innovation is lacking in the forest products industry due to lack of research and development. Properly managing and promoting employee innovation and creativity are direct avenues the forest products industry should be taking to combat high needs for research and development.

References

- Energy-in-Motion. Available at <http://www.energy-in-motion.com>. Last Accessed Apr. 2, 2012

- Fricke, Christian F. “Lean Management: Awareness, Implementation Status, and Need for Implementation Support in Virginia’s Wood Industry.” Virginia Tech. (2010). Last Accessed Feb. 17, 2012

- U.S. Energy Information Administration (EIA). Use of Electricity- Basics. 2011. Available at <http://www.eia.gov/energyexplained/index.cfm?page=electricity_use>. Last Accessed Sep. 13, 2011

- United States. Energy Information Administration. Renewable Energy Is Used in All Sectors of the U.S. Economy. 2010. Web. <http://www.eia.gov/todayinenergy/detail.cfm?id=3870>.

- United States. Energy Information Administration. Voluntary Reporting of Greenhouse Gases Program: Fuel Emission Coefficients. 2011. Available at <http://www.eia.gov/oiaf/1605/coefficients.html>. Last Accessed Apr. 2, 2012

- United States. Environmental Protection Agency. Energy Trends in Selected Manufacturing Sectors: Opportunities and Challenges for Environmentaly Preferable Energy Outcomes. Fairfax: ICF Internaional, 2007. Last Accessed Feb. 17, 2012