By Joseph Pomponi. Email jpp5251@vt.edu

Vertical integration is the degree to which a firm owns its upstream suppliers and its downstream buyers (Racher 2010). There are three varieties: backward (upstream) vertical integration, forward (downstream) vertical integration, and balanced (both upstream and downstream) vertical integration (Racher 2010). Vertical integration within a company can help improve its processes by having all of the steps involved of producing a product under the control of that company. For an example of balanced vertical integration, a wood products company using vertical integration would have control of harvesting the raw material from the forest, converting the logs using technologies such as debarkers, saws, presses, sanders, etc. to produce the product they are specialized for, storing said product, and eventually marketing/retailing it out. If the company just had access to the harvesting and the inputs that would be backward (upstream) vertical integration, while if it just had control of retail and distribution centers that would be considered forward (downstream) vertical integration.

The concept of vertical integration also brings about the worry of monopolizing the market since all of the process would be under one parent company. However, Richard Mpoyi (2003) suggests “So to support the competitive strength of their companies, managers that intend to change the levels of vertical integration may look at their competitors’ levels, but more importantly they should base their decisions on relevant organizational characteristics.” While certain companies may do better with a vertical integration process, not all companies need to implement it; it all depends on their structure and own company goals. The analysis showed that 50 percent of companies did not change their levels of vertical integration over the period 1980- 1997. This result suggests that once certain levels of vertical integration have been reached, these companies did not see that changing them would improve their ability to compete (Mpoyi 2003). Essentially, once a certain level of competitiveness is reached, it is not worth the time, money, and effort to keep introducing new technologies to try to keep up the vertical integration.

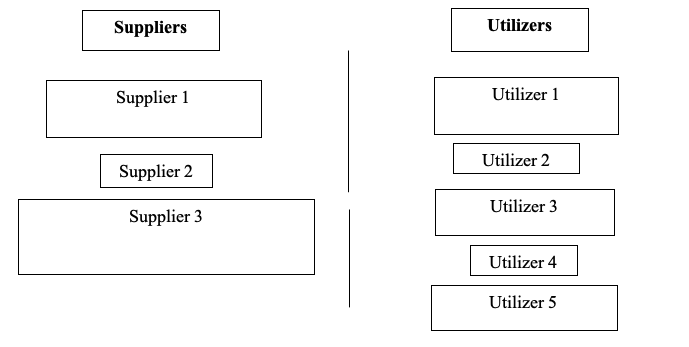

The main issue that arises with attempting to vertically integrate wood products companies is that land in the United States of America is either public or private. When establishing an integrated wood products industry around, consideration must be given to not only the quantity and quality of the wood supply, but also to the reliability of the supply over time. The best way to reduce the risk to investments associated with feedstock supply is to have a variety of land ownerships. For example, only having federal lands as a wood supply is very risky because that supply will be subject to the politics and bureaucracy associated with federal agencies (Racher 2010). Large private land parcels can lead to either investments in wood products industries not being made or those industries having the wood supply compromised by pricing (Racher 2010). Since in the USA land is split between public and private, wood products companies have issues with attempting to have a balanced vertically integrated process. This leads to most of these companies either having an upstream or downstream process, so they would have to outsource either their supply or their product. Construction companies would then have to contact multiple suppliers to try and search for the product they need for what they are building. An example of a low-scale wood products industry is represented in Figure 1 (Racher 2010).

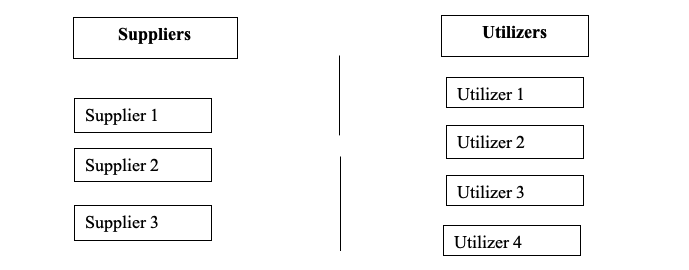

This figure would be representative of low-tech wood product industries such as firewood production and post production. As evidenced, the supplier and the utilizer side are separated, thus not using a vertically integrated system. However, since the concern of the monopolization of the market is present, having a diversity of suppliers who harvest the material to provide the raw material needed for the construction industry is ideally the most sustainable system. Figure 2 represents the idea of a balanced supplier and utilizer relationship (Racher 2010). The size of the boxes is supposed to represent the size of the supplier and utilizer.

As previously discussed, the idea of monopolization in the wood products industry is a concern, and vertical integration could be seen as an enabler of monopolization. The fact of the matter is because of the privatization of land, integrating wood products in the way of vertical integration is quite difficult. Companies either use upstream or downstream vertical integration as a way to sort of compromise this fact. The issues that construction companies face is the same sort of idea; the fact that they don’t have vertical integration in the means of they don’t have their own equipment and land to get the raw material needed to build their projects. They count on suppliers of wood products to get the material they need. Usually the process of determining a supplier is through bidding. Different factors affect the construction company’s decision of what supplier they want to proceed with. Those factors include: cost, quality, location, the relationship, and flexibility of these suppliers.

So, why is any form of vertical integration important to these wood products and construction companies? Construction companies know what they are looking for in terms of product, and having to choose a supplier through an extensive process is a burden. Most of these types of companies have downstream vertical integration where they have warehouses and distribution centers full of the material needed for their projects. Through vertical integration a firm by-passes or, more economically speaking, encompasses a market nexus (Adelman 1955). The idea of vertical integration would allow these companies to easily get to the raw material they need in a quicker time. For wood product companies, most of them have market share in the harvesting and production department (so upstream vertical integration where they have control over the production of the products needed for construction companies.). Where the wood products industry falls short, is not having their own distribution centers or retail sites, thus they would have to be a sort of middle man to the construction industry which could lead to them not getting as much of as a profit as they desire. Both of these industries coincide with each other; the wood products industry making products for the construction industry to use. If these industries can work to vertically integrate more of their processes, it would lead to an easier time of producing the product, harvesting the material they need, and selling their product.

Works Cited

- Adelman, M. A. 1955. “ Concept and Statistical Measurement of Vertical Integration.” National Bureau of Economic Research. pp. 281–330.

- Mpoyi,Richard. 2003. “Vertical Integration: Strategic Characteristics and Competitive Implications”. Competitiveness Review: An International Business Journal. 13(1): 44-55

- Racher, Brett. 2010. “Integration of the Wood Products Industry.” Southwest Sustainable Forest Partnership. Jan.