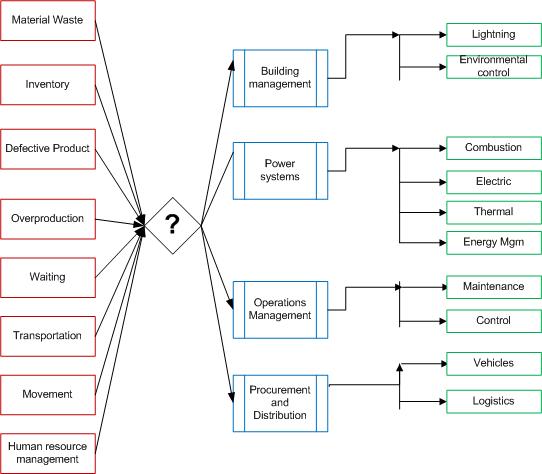

Representatives from private, goverment, non goverment, and academic sectors attended the workshop Energy Savings using Lean Thinking held at the Riverstone Energy Center in South Boston, VA. This workshop delivered academic and practical applications on how industries in the wood products sector could decrease energy consumption by integrating lean thinking principles with energy management methods. Standard energy audits are oriented to the identification of energy management opportunities (EMOs) by looking at the power systems, building infraestructure, and control systems but most of the times they do not consider the impact of management practices in energy consumption. This workshop gave participants academic and practical guidelines in how to integrate lean thinking with energy reduction efforts. Figure 1 shows the model being developed at Virginia Tech.

In the firs presentation, Mr. Mark Webber from Dominion reviewed the current status and future of energy in Virginia. The second presentation was given by Dr. Earl Kline from Virginia Tech on Lean Thinking Principles. After this, attendess were introduced to a Lean Energy Audit Toolkit (integraton of Lean Thinking concepts and EMOs) at macro level to identify what areas in their processes require inmediate attention, followed by examples of wood products industries that have achieved significant energy savings by eliminating waste in their processes. This presentation was given by Dr. Henry Quesada also from Virginia Tech.

The last two presentations were practical approaches. Mr. Tyler Gill from Enernoc presented on Enernoc’s energy management platforms. Mr. Gill used a real-time example to demostrate how important is to constantly monitored energy consumption in order to identify potential EMOs. Finally, Mr. Shannon Walls from Masco Cabinetry Group presented results of how his Continous Improvement (CI) Group has identified, quantified, and implemented EMOs using CI methods. Overall, 64% out of the 23 attendees rated the workshop as excellent and 36% as good.

Please feel free to contact Dr. Henry Quesada at quesada@vt.edu if you have any questions about EMOs and integration with Lean Thinking concepts.