Introduction of CE:

Concurrent engineering is an effective methodology used for improving engineering quality and reducing lead time. Sprague, Singh, and Wood (2002) defined concurrent engineering as “a systematic approach to the integrated, concurrent design of products and their related processes, including manufacture and support.” One of the biggest applicants of the concurrent engineering approach is the aerospace industry where different functional teams worked in parallel and the development process results could be rapidly verified from multiple options (Rush and Roy 2000). The most phenomenal result of concurrent engineering compared to the traditional sequential engineering is the reduction of product development lead time, appreciation of total quality (quality of process, quality of organization, and product quality), increased productivity, and decreased costs (costs of rework, scrap, and delays) (Ghodous, Vandorpe, and Biren Prasad 2000).

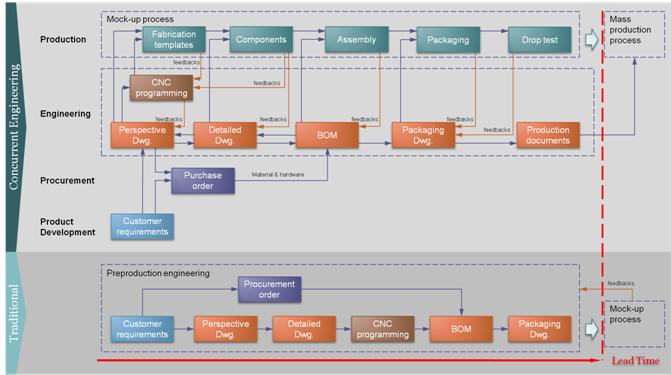

Synchronize team efforts in the furniture engineering process – CE

CE could also improve the furniture engineering process. Figure 1 shows the difference between concurrent engineering and traditional engineering in a engineering furniture process. In concurrent engineering, the engineering process is paralleled with the mock-up process so that; a great deal of time is saved because engineering could response to any error caused by a design flaw based on daily production feedbacks. Thus by the end of engineering process, the mass production engineering documents are ready by using the same amount of time whereas in sequential engineering, only preproduction documents are completed.

Things are different in the traditional engineering process. The preproduction engineering happens first then the documents will distribute to production to trigger the mock-up process. Production associates will provide feedbacks in the process of making mock-ups. Engineers cannot start the compilation of mass production documents until all the feedbacks are collected from production. Obviously, the traditional engineering takes a lot of engineering iterations, whereas the concurrent engineering requires less engineering design cycles. Also, because feedbacks are given on timely basis, it helps to enhance the design productivity, ensure the product quality, and shorten the lead time.

Benefits of concurrent engineering

- CE could ensure the quality of drawings because the feedbacks from the mock-up process are kept up to date and engineers could find the design problems in the first place. Furthermore, although the concurrent engineering cannot guarantee to increase the speed of the generation of drawings, the elimination of preproduction engineering process, the total lead time of creating engineering drawings is significantly reduced compared to traditional engineering.

- The just-in-time mock-up feedbacks could also unburden a great deal of workload for the engineering supervisors because they do not have to check the whole production documents from beginning to the end. At this point, the design errors have been already modified by the product engineers.

- Engineers do not have to compile mass production documents based on the mock-up feedbacks as in the traditional engineering process. With CE, the engineers could work on changes immediately. On the other hand, CE synchronizes the preproduction process and engineering process which saves a great portion of engineering lead time. This means the engineering process could be more time-efficient and productive.

References:

- Ghodous, P., D. Vandorpe, and Biren Prasad. 2000. Advances in concurrent engineering, CE2000: presented at Seventh ISPE International Conference on Concurrent Engineering: Research and Applications, Lyon Cluade Bernard University, France, July 17-20, 2000. CRC Press, July 10.

- Rush, C., and R. Roy. 2000. Analysis of cost estimating processes used within a concurrent engineering environment throughout a product life cycle. Advances in Concurrent Engineering: Ce2000: 58.

- Sprague, R. A., K. J. Singh, and R. T. Wood. 2002. Concurrent engineering in product development. Design & Test of Computers, IEEE 8, no. 1: 6–13.