The implementation of Lean Product Development is based on applying lean principles to be able to gain more economic benefits. The goal is to focus on decreasing process variability, maintaining flow and reducing waste (Achieving Lean 2004).

Lean Product Development has been incorporated into organizations with the motivation of maintaining higher value and quality, shorten lead times, and lower costs This last one motivator was was not successful enough when conducting or implementing traditional product development process (Leon et al, 2011).

Ward (2007) states that to provide better understanding in implementing lean product processes, manufacturers need to seek for the importance and the purpose of product development, product itself, good development system and value in product development.

Commonly, Lean is mostly found proper for manufacturing process related with material supply, component production, and delivery of products. Nevertheless, besides manufacturing operations lean thinking can also be applied to Lean Product Development (LPD) (Morgan and Liker, 2006). The difference between LPD and traditional product development is specifically the underlying of the numerous benefits by using the LPD’s own flow over the whole process (Karlsson and Ahlstrom, 1996). Supplier involvement is one technique used in the LPD that targets the incorporation of suppliers at the beginning of the process other than in some parts of the project. Simultaneous engineering (or concurrent engineering) term is used in this process and it can be defined in a simple was as driving in parallel different activities (Karlsson and Ahlstrom, 1996).

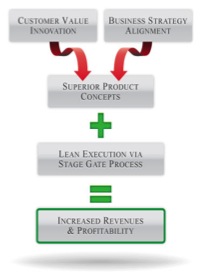

Most of companies have adjusted state-gate process in order to deliver value to all stakeholders by decreasing waste and smoothing the value stream in product development processes. There are two notable benefits with regard to this concept, (a)better design activities improvement with the adjustment of tools in lean and (b) integration with lean among marketing research, conceptual design, product design, test and verification, and ramp-up product (Wang et al, 2011).

References

- Anonymous. 2004. Achieving lean product development. Strategic Direction, 20(7/8), 33.

- Karlsson, C., & Åhlström, P. (1996). The difficult path to lean product development. Journal of Product Innovation Management, 13(4), 283-295.

- León, H.,C.Mart, & Farris, J. A. (2011). Lean product development research current state and future directions. Engineering Management Journal, 23(1), 29-51

- Morgan, J. M., & Liker, J. K. (2006). The Toyota product development system. New York: Productivity press.

- Wang, L., Ming, X. G., Kong, F. B., Li, D., & Wang, P. P. (2011). Focus on implementation: a framework for lean product development. Journal of Manufacturing Technology Management, 23(1), 4-24.

- Ward, A. C. (2007). Lean product and process development. Lean Enterprise Institute.