The growth of international trade in the last decades created the need to improve not only transportation infrastructure and technology, but also the elements used during transportation process such as handling, loading, unloading, warehousing. One of these elements is the pallet. Pallets and containers play an important role in the movement of goods from place to place. They are not only used in warehouses or commercial centers, but also in all those activities that require an efficient way of transportation. Pallets allow reducing time and cost in an efficient manner, facilitating handling and transportation of raw and in-process materials, or finished products from the supplier to the manufacturer, from the manufacturer to the wholesaler, and then to the retailer. About 450 million new pallets are manufactured in the US each year, 1.9 billion are in use in the U.S. each year, and 300 million pallets are recovered by pallet recyclers each year.

Pallets definition

Pallets are the interface between packaging and the unit load handling equipment (White & Hamner, 2005). Another simpler definition is that pallets are “portable platforms”, which facilitates the movement and storage of unitized goods (Kator, 2008).

Unit loads are also important to define, as the system comprised of pallets, packaging materials, and unit load stabilizers (stretch wrap, tie sheets, corner posts, load adhesives, and strapping). Figure 1-1 shows two examples of pallets and unit loads.

Figure 1-1. Pallets and Unit load

Wood Pallet and Containers Imports in the U.S. Market

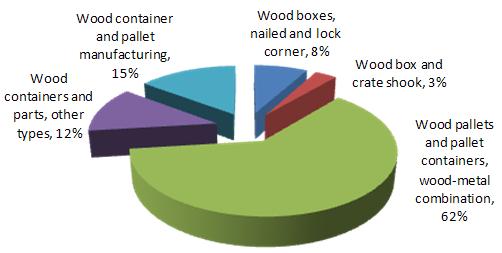

According to the North American Industry Classification System (NAICS), the Wood Pallet and Container product class is represented by the following sub-classes which show percentages, representing the average share of each sub-class on the total value of shipments for years 2002 to 2006. Wood pallets and containers, and wood-metal combinations made up 62% of the total product class’ value of shipments.

Figure 1‑2. Share of Product Sub-Categories on Wood Pallet and Container Manufacturing Product Class (based on value of shipments, Census Bureau 2009)

U.S Domestic Production

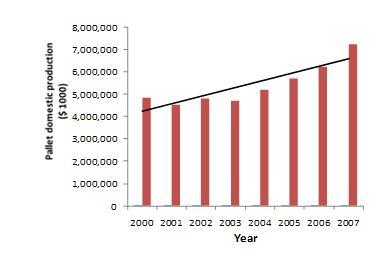

The U.S. domestic production is showed in the figure 1-3 bellow. It is evident from Figure 1.3 that exists an increase over the years. In 2000 the domestic production was $ 4,8 billion and for 2007 was 7,2 billion representing a 49% of increase in 7 years.

Figure 1-3. U.S. Pallet Domestic Production (Census Bureau 2009)

U.S. Imports

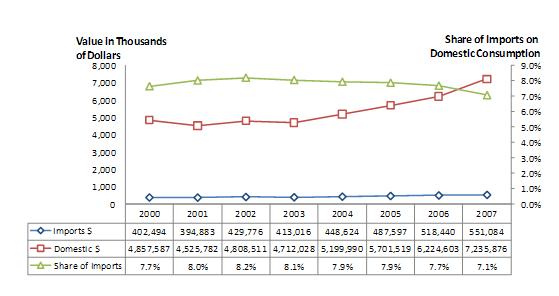

Figure 1-4 shows the total imports and value of shipments (domestic production) of wood pallets and containers, and the share of imports over total domestic consumption. The later was obtained by adding imports and value of shipments. The value of product shipments (domestic production) has grown from about $5 billion to $7.2 billion over the 8-year period. Imports have stayed almost constant throughout those years. As a result, the share of imports on the domestic consumption of wood pallet and containers, has decreased, from 7.7% in year 2000 to 7.1% in year 2007; a drop of 8%.

Figure 1-4. Wood Pallets and Container Imports and Domestic Production (Census Bureau 2009)

Regarding countries of origin for imports, Figure 1-5 shows the ten major exporters of Wood pallets and containers to the U.S. from year 2000 to 2008.

Figure 1-5. Ten Major Country Exporters of Wood Pallets and Containers to the U.S. in the year 2008 (Census Bureau 2009)