The Forest Products Industry has made a concerted effort to reduce operating expenses in order to stay competitive in the global marketplace. Manufacturers have applied lean thinking and energy management programs to help them identify and address inefficiencies but the systems work independent of each other which diminishes their overall value and benefit. Developing a methodology that applies lean thinking to correlate energy consumption with throughput would provide a valuable resource for the industry.

Lean thinking is a process improvement that focuses on increasing value-added processes and decreasing non-value-added processes (Womack and Jones, 2003). Value is determined by the customer (Womack and Jones, 2003). Eliminating or reducing non-value-added processes can increase production rates for value-added-processes (Liker, 2003). By eliminating or reducing non-value-added processes, energy efficiency is improved.

After a company has bought into the concept of becoming “lean” they must first identify both value added and non-value added steps within a process. However, identifying value added contribution of various process steps is difficult to do without seeing the entire process. Value stream mapping (VSM) is a way of showing how material/products and information flow through the entire production process (Rother and Shook, 2003). When taking a value stream approach it is important to focus on the big picture and not just individual processes. Rother and Shook (2003) state that “a value stream is all the actions (both value added and non-value added) currently required to bring a product through the main flows essential to every product.” When mapping out the current process it is generally recommended to start the map beginning with the customer and then mapping subsequent upstream processes to the supplier or raw materials. In doing so, it allows production to view the process from the customers view point thus, allowing the customer to determine value and non-value added processes.

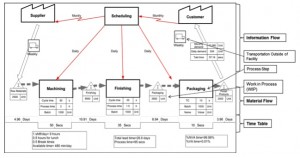

Figure 1 is an example of how a VSM measures the flow of material and information through a production process. The flow of material provides detailed information about each process step within the entire production process. VSM is a superior mapping tool compared to alternative mapping tools, because it provides detailed information specific to each process step. Detailed information within a VSM includes; takt time, cycle time, change-over time, available time, scrap rate, number of operators, throughput, and downtime (Rother and Shook, 2003). The recording of detailed process information allows a process manager to see crucial areas in need of improvement and the effects of those improvements. In this research, electrical consumption is significant detailed process information that can be recorded and categorized based on each process step.

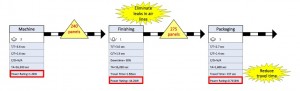

Figure 2 is an example of how detailed information for each process step will be recorded within a VSM. VSM displays information so that it can be compared to other process steps and how they contribute to the overall production times and values. Highlighted in red, is the total estimated power rating for each process step. By multiplying the power rating by the total available time, kilo-watt hour per day can be determine for each process. Estimating electrical consumption for each process step allows process managers the ability to associate production values and times with electrical consumption. For example, Figure 2 illustrates the process step finishing having a power rating of 44.2kW as well as 30% downtime. Finishing is a high electrical consuming area that needs to be evaluated for potential process and energy improvements. In Figure 2, finishing is considered to be a possible improvement area provoking a kaizen burst to be performed to eliminate leaks in air lines for the process step.

VSM is an extremely effective tool for measuring production times and values. Incorporating electrical consumption into the VSM allows process managers the ability to see the impact process improvements have on reducing electrical consumption and vice versa. VSM identifies value-added and non-value-added process steps, which, is extremely crucial when incorporating lean thinking and reducing or eliminating wasted electrical consumption. By taking a lean manufacturing approach, electrical consumption can be categorized as value-added and non-value-added allowing customers to determine electrical waste. For future research, it is suggested to develop a method for determining the direct and indirect electrical consumption that can be incorporated into a VSM.

References

- Liker, Jeffrey K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer. New York: McGraw-Hill, 2004. Last Accessed Feb. 17, 2012

- Rother, Mike, and John Shook. Learning to See: Value-Stream Mapping to Create Value and Eliminate Muda. 1.3. Massachusetts: The Lean Enterprise Institute, 2003. Last Accessed Feb. 17, 2012

- Woamck, J. P. and D. T. Jones. 2003. Lean Thinking: Banish Waste and Create Wealth In Your Corporation. Second edition. Simon & Schusters. New York. Last Accessed Feb. 17,