Description

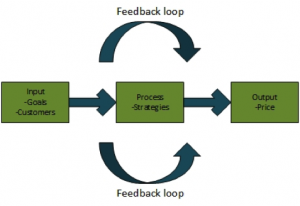

An important component of manufacturing cost is energy management and more needs to be done throughout the region to provide effective and efficient training programs that help the industry to understand and implement best energy management practices. The proposed workshops will introduce the concept of lean thinking and how this concept impacts energy consumption. Tools to identify waste will be introduced and procedures to calculate potential savings will be demonstrated using existing energy recommendations databases. Case studies will be presented to demonstrate how energy management practices have been implemented in similar industries.

Content

- Introduction to lean manufacturing. How is lean manufacturing related to energy savings?

- Value stream mapping (VSM)

- Incorporation of energy consumption into VSM

- Using energy management systems (EMS) for decision making

- Data mining

- Data analysis

- Decision making

- Energy audits. Integration with lean tools

- Case of study 1: best energy saving recommendations

- Case of study 2: Kaizen groups and impact on energy consumption

- Group activity: Data mining and trend analysis of energy consumption.

Location and date

The workshop starts at 8: 30 am and ends at 4:30 pm.

- Marion, VA. November 20, 2014. Venue: Smith County Office. 121 Bagley Circle, Suite 100, Marion, VA 24354

Registration

The event is sponsored through a grant from the Virginia Tobacco Indemnification & Community Revitalization Commission. However, a $25 registration fee will be charged to cover materials, coffee breaks, and lunch. To register, please download the registration form and mail it with your payment to:

Linda Jones, VCE-Central District, 150 B Slayton Avenue, Danville, VA 24540

Please contact Dr. Henry Quesada at quesada@vt.edu or 540 231-0978 if you need further details.

Instructor

Dr. Henry Quesada is an associate professor at the Department of Sustainable Biomaterials at Virginia Tech. Henry has a B.S. in Industrial Engineering and a M.Sc and Ph.D. from Purdue University. He has organized and delivered over 65 workshops impacting more than 2,500 people in the areas of continuos improvement, supply chain management, and marketing applied to the forest products industry. For a detailed bio of Dr. Quesada please follow this link.

Non-discrimination Statement

Virginia Cooperative Extension programs and employment are open to all, regardless of race, color, national origin, sex, religion, age, disability, political beliefs, sexual orientation, genetic information, marital, family, or veteran status, or any other basis protected by law. An equal opportunity/affirmative action employer.

ADA Statement

If you are a person with a disability and desire any assistive devices, services or other accommodations to participate in this activity, please contact Henry Quesada at 540-2310978/TDD* during business hours of 8 a.m. and 5 p.m. to discuss accommodations 5 days prior to the event. *TDD number is 800-828-1120

Sponsors

IUFRO Division 5. Research Party 5.04.13: Industrial Engineering, Operation Analysis, and Logistics